Battery Welding

Copper - Nickel - Automation

Sunstone Battery Welding systems allow you to weld highly conductive metals such as pure copper and aluminum, or traditional metals like nickel. They also come in a CNC version that is capable of performing all the same tasks with the assistance of a CNC table.

What are you welding today? Call or text us at +1-801-658-0015.

-

Original price $3,900.00 - Original price $3,900.00Original price$3,900.00$3,900.00 - $3,900.00Current price $3,900.00| /

Parallel Weld Head

Sunstone WeldersIn stockParallel Weld Head The WH2 pneumatic parallel weld heads offer precision and repeatability at an affordable price. The WH2 weld heads offer paralle...

View full detailsOriginal price $3,900.00 - Original price $3,900.00Original price$3,900.00$3,900.00 - $3,900.00Current price $3,900.00| / -

Original price $31,500.00 - Original price $31,500.00Original price$31,500.00$31,500.00 - $31,500.00Current price $31,500.00| /

Omega PA250i Welding System

Sunstone WeldersIn stockOmega PA250i Welding System The Case for Copper One of the biggest challenges when welding EV batteries is finding a welder capable of welding hig...

View full detailsOriginal price $31,500.00 - Original price $31,500.00Original price$31,500.00$31,500.00 - $31,500.00Current price $31,500.00| / -

Original price $7,800.00 - Original price $13,200.00Original price$7,800.00 - $13,200.00$7,800.00 - $13,200.00Current price $7,800.00| /

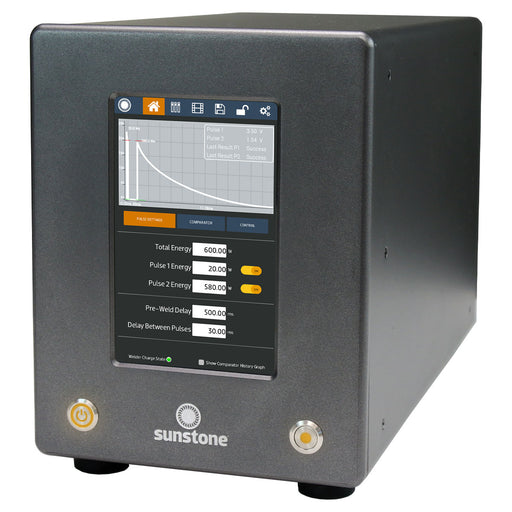

Micro Resistance - Advanced Dual Pulse CD Spot Welder

Sunstone WeldersIn stockADVANCED FINE-SPOT RESISTANCE WELDERS Feedback reporting PLC connectivity Full weld head control 200ws, 400ws, 600ws or 1200ws power Roll spot C...

View full detailsOriginal price $7,800.00 - Original price $13,200.00Original price$7,800.00 - $13,200.00$7,800.00 - $13,200.00Current price $7,800.00| / -

Original price $13,200.00 - Original price $13,200.00Original price$13,200.00$13,200.00 - $13,200.00Current price $13,200.00| /

High Power - Micro Resistance - Advanced CD Spot Welder

Sunstone WeldersIn stockADVANCED FINE-SPOT RESISTANCE WELDERS Capacitive Discharge (CD) resistance welders have many advantages over other welder types. Since CD welders u...

View full detailsOriginal price $13,200.00 - Original price $13,200.00Original price$13,200.00$13,200.00 - $13,200.00Current price $13,200.00| /