Honeycomb

Easily and Quickly Create Honeycomb Panels

The industries prefer the honeycomb strength-to-weight ratio and that lighter materials, like aluminum, titanium, Iconel®, and Hastelloy®, can be used in the production process. Sunstone’s welding technology easily fastens both similar and non-similar metals together, regardless of type of metal or thickness, to easily and quickly create honeycomb panels or cores.

Expanded Manufacturing Flexibility with a Sunstone

Depending on how the honeycomb panel will be used, a Sunstone micro welder can efficiently weld and manufacture the core structure. Or, with the ability to quickly tack and join the face sheets to tops and bottoms, a Sunstone micro welder can easily create a composite honeycomb sandwich panel. Sunstone’s honeycomb welder experts can help you choose the right solution.

Common Honeycomb Welding Applications

- Core Honeycomb Lattice Welding

- Seam Welding

- Tacking Face Panels to Core Lattice

- Honeycomb Sandwich Manufacturing

What are you welding today? Call or text us at +1-801-658-0015.

-

Original price $1,750.00 - Original price $1,750.00Original price$1,750.00$1,750.00 - $1,750.00Current price $1,750.00| /

Mini Grip

Sunstone WeldersIn stockThe Sunstone Mini Grip Key Features Smaller size and weight reduces operator fatigue Accepts any 1/8” electrode Standard collet electrode system ...

View full detailsOriginal price $1,750.00 - Original price $1,750.00Original price$1,750.00$1,750.00 - $1,750.00Current price $1,750.00| / -

Original price $3,900.00 - Original price $3,900.00Original price$3,900.00$3,900.00 - $3,900.00Current price $3,900.00| /

Opposed Weld Head

Sunstone WeldersIn stockOpposed Weld Head The WH1 weld heads offer opposed weld electrodes and are ideal for general fine spot opposed resistance welding. The standard ele...

View full detailsOriginal price $3,900.00 - Original price $3,900.00Original price$3,900.00$3,900.00 - $3,900.00Current price $3,900.00| / -

Original price $275.00 - Original price $275.00Original price$275.00$275.00 - $275.00Current price $275.00| /

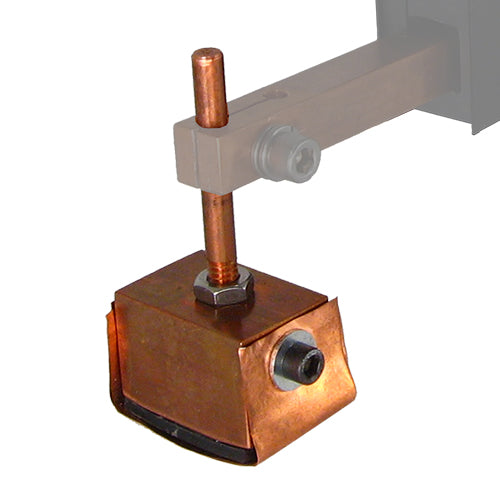

Honeycomb Micro Welding Electrodes

Sunstone WeldersIn stockFlat Honeycomb Tack Welding Electrodes and Radius Honeycomb Tack Welding Electrode. For use with Sunstones micro welding attachments. Best used wit...

View full detailsOriginal price $275.00 - Original price $275.00Original price$275.00$275.00 - $275.00Current price $275.00| / -

Original price $7,800.00 - Original price $13,200.00Original price$7,800.00 - $13,200.00$7,800.00 - $13,200.00Current price $7,800.00| /

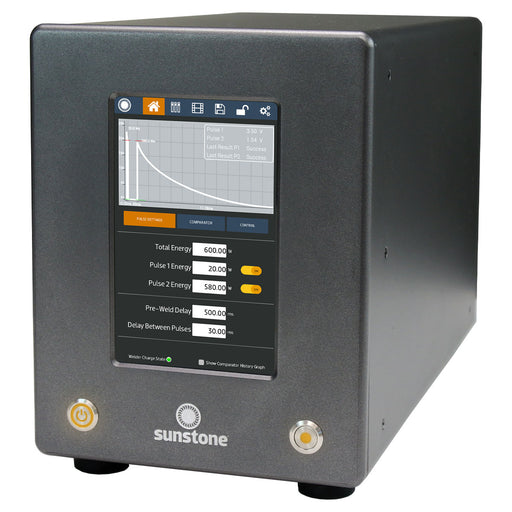

Micro Resistance - Advanced Dual Pulse CD Spot Welder

Sunstone WeldersIn stockADVANCED FINE-SPOT RESISTANCE WELDERS Feedback reporting PLC connectivity Full weld head control 200ws, 400ws, 600ws or 1200ws power Roll spot C...

View full detailsOriginal price $7,800.00 - Original price $13,200.00Original price$7,800.00 - $13,200.00$7,800.00 - $13,200.00Current price $7,800.00| / -

Original price $1,900.00 - Original price $3,200.00Original price$1,900.00 - $3,200.00$1,900.00 - $3,200.00Current price $1,900.00| /

PG2

Sunstone WeldersIn stockPistol Grip Hand Piece with Button Trigger. Accepts threaded electrodes. Can be used as a single probe or roll spot.Cables: 1 AWGWeight: 5 lb / 2.2...

View full detailsOriginal price $1,900.00 - Original price $3,200.00Original price$1,900.00 - $3,200.00$1,900.00 - $3,200.00Current price $1,900.00| / -

Original price $15,500.00 - Original price $15,500.00Original price$15,500.00$15,500.00 - $15,500.00Current price $15,500.00| /

PA250i Micro TIG Welder

Sunstone WeldersIn stockPA250i Micro TIG Welder Maximum Power!The most powerful Sunstone pulse arc welder delivers 250 joules of energy with precision and accuracy When yo...

View full detailsOriginal price $15,500.00 - Original price $15,500.00Original price$15,500.00$15,500.00 - $15,500.00Current price $15,500.00| / -

Original price $13,200.00 - Original price $13,200.00Original price$13,200.00$13,200.00 - $13,200.00Current price $13,200.00| /

High Power - Micro Resistance - Advanced CD Spot Welder

Sunstone WeldersIn stockADVANCED FINE-SPOT RESISTANCE WELDERS Capacitive Discharge (CD) resistance welders have many advantages over other welder types. Since CD welders u...

View full detailsOriginal price $13,200.00 - Original price $13,200.00Original price$13,200.00$13,200.00 - $13,200.00Current price $13,200.00| /