Pulse Arc Welders (TIG)

Filters

-

Original price $2,400.00 - Original price $3,000.00Original price$2,400.00 - $3,000.00$2,400.00 - $3,000.00Current price $2,400.00| /

Orion mPulse Pulse Arc Welder

Sunstone WeldersIn stockWith a 30ws power potential, the mPulse can be used by almost anyone and has the power to tackle all sorts of jobs. It’s perfect for those needing ...

View full detailsOriginal price $2,400.00 - Original price $3,000.00Original price$2,400.00 - $3,000.00$2,400.00 - $3,000.00Current price $2,400.00| / -

Original price $4,500.00 - Original price $4,500.00Original price$4,500.00$4,500.00 - $4,500.00Current price $4,500.00| /

Orion 100c Pulse Arc Welder - More Energy and Capability

Sunstone WeldersIn stockThe Orion 100c Pulse Arc Welder is uses advanced technology for precision micro welds! The Orion 100c pulse arc welder provides power up to 100 jo...

View full detailsOriginal price $4,500.00 - Original price $4,500.00Original price$4,500.00$4,500.00 - $4,500.00Current price $4,500.00| / -

Original price $5,900.00 - Original price $9,200.00Original price$5,900.00 - $9,200.00$5,900.00 - $9,200.00Current price $5,900.00| /

Orion 150s Pulse Arc Welder - Our best selling model!

Sunstone WeldersIn stockOrion 150s Pulse Arc Welder The Precision Micro-Welder Technology You Need! The Orion 150s boasts a power potential of up to 250 joules of pulse-a...

View full detailsOriginal price $5,900.00 - Original price $9,200.00Original price$5,900.00 - $9,200.00$5,900.00 - $9,200.00Current price $5,900.00| / -

Original price $8,500.00 - Original price $8,500.00Original price$8,500.00$8,500.00 - $8,500.00Current price $8,500.00| /

Orion 200i Pulse Arc Welder - For those that want it all!

Sunstone WeldersIn stockOrion 200i Pulse Arc Welder The Most Capable Orion Pulse Arc Welder is Ready for Your Shop! Sunstone’s Orion 200i Welder Provides: A very small h...

View full detailsOriginal price $8,500.00 - Original price $8,500.00Original price$8,500.00$8,500.00 - $8,500.00Current price $8,500.00| / -

Original price $31,500.00 - Original price $31,500.00Original price$31,500.00$31,500.00 - $31,500.00Current price $31,500.00| /

Omega PA250i Welding System

Sunstone WeldersIn stockOmega PA250i Welding System The Case for Copper One of the biggest challenges when welding EV batteries is finding a welder capable of welding hig...

View full detailsOriginal price $31,500.00 - Original price $31,500.00Original price$31,500.00$31,500.00 - $31,500.00Current price $31,500.00| / -

Original price $999.00 - Original price $999.00Original price$999.00$999.00 - $999.00Current price $999.00| /

Zapp™ Permanent Jewelry Welder for Beginners

Sunstone WeldersIn stockZapp™ Permanent Jewelry Welder for Beginners The Zapp is an entry-level permanent jewelry welder that helps novice PJ artists start and grow their ...

View full detailsOriginal price $999.00 - Original price $999.00Original price$999.00$999.00 - $999.00Current price $999.00| / -

Original price $2,800.00 - Original price $3,800.00Original price$2,800.00 - $3,800.00$2,800.00 - $3,800.00Current price $2,800.00| /

Orion PJ The Original Permanent Jewelry Welder™

Sunstone WeldersIn stockThe Orion PJ pulse arc welder was designed specifically for permanent jewelry artists for fine chain welding. Simple Touchscreen Control Power Ran...

View full detailsOriginal price $2,800.00 - Original price $3,800.00Original price$2,800.00 - $3,800.00$2,800.00 - $3,800.00Current price $2,800.00| / -

Original price $1,299.00 - Original price $1,699.00Original price$1,299.00 - $1,699.00$1,299.00 - $1,699.00Current price $1,299.00| /

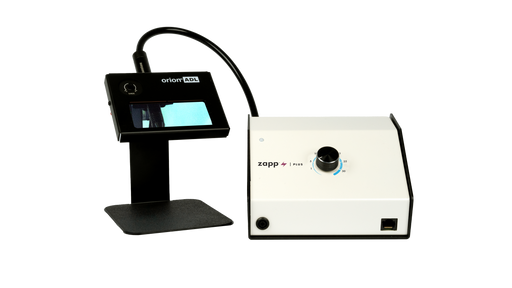

Zapp Plus™ — Budget Permanent Jewelry Welder

Sunstone WeldersIn stockZapp Plus™ — Budget Permanent Jewelry Welder™ The Zapp Plus is an entry-level permanent jewelry welder with more power and an advanced stylus. T...

View full detailsOriginal price $1,299.00 - Original price $1,699.00Original price$1,299.00 - $1,699.00$1,299.00 - $1,699.00Current price $1,299.00| / -

Original price $500.00 - Original price $500.00Original price$500.00$500.00 - $500.00Current price $500.00| /

Orion Upgraded ADL

Sunstone WeldersIn stockThe Upgraded ADL provides customers with an improved welding experience with these key features: Large 4X6 view screen for easier viewing Clear sc...

View full detailsOriginal price $500.00 - Original price $500.00Original price$500.00$500.00 - $500.00Current price $500.00| /