Automotive

Ultra Precision for Reliability and Safety

An efficient solution for automotive welding starts here! Whether you’re building ignition controls, instrumentation, O2 sensors, potentiometers, solenoids, battery packs, or motor assemblies, only Sunstone delivers a level of accuracy and reliability equal to your reputation. For automotive welding, when passenger safety is paramount, choose a Sunstone micro welder to create a dependable weld time and time again.

Maximum Energy Control for Expanded Flexibility

Sunstone micro welders let you dial in the exact amount of energy required for any application: cross wire welding, bench-top production line welding, electric vehicle power cells, electronic components, and more! Sunstone’s energy management features let you tackle any micro-welding challenge, from fuel injector welding to airbag initiators to electrical fuses.

-

Original price $3,500.00 - Original price $4,500.00Original price$3,500.00 - $4,500.00$3,500.00 - $4,500.00Current price $3,500.00| /

Micro Resistance - Single Pulse CD Spot Welders

Sunstone WeldersIn stockSingle Pulse Micro Spot Resistance Welding Equipment Features: Refined Control of Weld Energy LCD Display with Exact Energy Read-Out Audio Beeps –...

View full detailsOriginal price $3,500.00 - Original price $4,500.00Original price$3,500.00 - $4,500.00$3,500.00 - $4,500.00Current price $3,500.00| / -

Original price $9,000.00 - Original price $9,000.00Original price$9,000.00$9,000.00 - $9,000.00Current price $9,000.00| /

Wave AC The World's Most Advanced AC Welder

Sunstone WeldersWave AC: The World's Most Advanced AC Welder The Sunstone Wave AC is the world’s most advanced AC resistance welder capable of delivering up to 2,7...

View full detailsOriginal price $9,000.00 - Original price $9,000.00Original price$9,000.00$9,000.00 - $9,000.00Current price $9,000.00| / -

Original price $7,800.00 - Original price $13,200.00Original price$7,800.00 - $13,200.00$7,800.00 - $13,200.00Current price $7,800.00| /

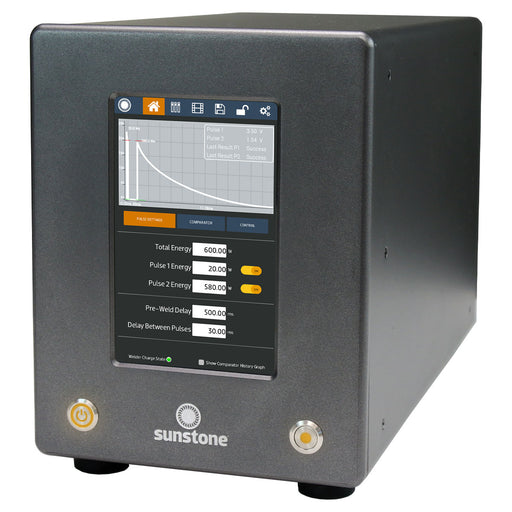

Micro Resistance - Advanced Dual Pulse CD Spot Welder

Sunstone WeldersIn stockADVANCED FINE-SPOT RESISTANCE WELDERS Feedback reporting PLC connectivity Full weld head control 200ws, 400ws, 600ws or 1200ws power Roll spot C...

View full detailsOriginal price $7,800.00 - Original price $13,200.00Original price$7,800.00 - $13,200.00$7,800.00 - $13,200.00Current price $7,800.00| / -

Original price $10,900.00 - Original price $10,900.00Original price$10,900.00$10,900.00 - $10,900.00Current price $10,900.00| /

The Pico™ - DC Closed-loop Feedback Resistance Welder

Sunstone WeldersIn stockThe Pico - DC Closed-loop Feedback Resistance Welder The Sunstone Pico DC is an advanced, closed-loop feedback direct-current resistance welder sp...

View full detailsOriginal price $10,900.00 - Original price $10,900.00Original price$10,900.00$10,900.00 - $10,900.00Current price $10,900.00| / -

Original price $15,500.00 - Original price $15,500.00Original price$15,500.00$15,500.00 - $15,500.00Current price $15,500.00| /

PA250i Micro TIG Welder

Sunstone WeldersIn stockPA250i Micro TIG Welder Maximum Power!The most powerful Sunstone pulse arc welder delivers 250 joules of energy with precision and accuracy When yo...

View full detailsOriginal price $15,500.00 - Original price $15,500.00Original price$15,500.00$15,500.00 - $15,500.00Current price $15,500.00| / -

Original price $10,000.00 - Original price $11,900.00Original price$10,000.00 - $11,900.00$10,000.00 - $11,900.00Current price $10,000.00| /

Orion LZR ECO Benchtop Laser Welders

Sunstone WeldersIn stockOrion LZR Eco Benchtop Laser Welders State-of-the-Art Micro Laser Systems Harnessing Light to Advance Your Art An Orion laser micro welder from Sun...

View full detailsOriginal price $10,000.00 - Original price $11,900.00Original price$10,000.00 - $11,900.00$10,000.00 - $11,900.00Current price $10,000.00| / -

Original price $13,200.00 - Original price $13,200.00Original price$13,200.00$13,200.00 - $13,200.00Current price $13,200.00| /

High Power - Micro Resistance - Advanced CD Spot Welder

Sunstone WeldersIn stockADVANCED FINE-SPOT RESISTANCE WELDERS Capacitive Discharge (CD) resistance welders have many advantages over other welder types. Since CD welders u...

View full detailsOriginal price $13,200.00 - Original price $13,200.00Original price$13,200.00$13,200.00 - $13,200.00Current price $13,200.00| / -

Original price $15,500.00 - Original price $22,500.00Original price$15,500.00 - $22,500.00$15,500.00 - $22,500.00Current price $15,500.00| /

Orion LZR Benchtop Laser Welder (Pro Series)

Sunstone WeldersIn stockThe Orion LZR: More Premium Features without the Cost! An Orion laser micro welder from Sunstone lets you accomplish extraordinary welds in the mos...

View full detailsOriginal price $15,500.00 - Original price $22,500.00Original price$15,500.00 - $22,500.00$15,500.00 - $22,500.00Current price $15,500.00| /