How Sunstone is Advancing Micro Welding Technology Through Partnerships with the AWS, RWMA, and EWI

I’ve seen firsthand how important it is to stay ahead of the curve when it comes to micro welding technology. As a company, we’ve always been committed to developing cutting-edge solutions, but as I’ve learned over the years, innovation can’t happen in a vacuum. To truly push the boundaries of what’s possible, we need the right partners—people and organizations who can help us expand our knowledge, refine our techniques, and open up new possibilities. That’s where our partnerships with AWS (American Welding Society), RWMA (Resistance Welding Manufacturing Alliance), and EWI (Edison Welding Institute) come in.

These relationships have become essential to our mission of advancing micro welding technology. They don’t just help us as a company—they allow us to better serve manufacturers who rely on precise, high-quality welding solutions to meet their production needs. Together with AWS, RWMA, and EWI, we’re driving innovation in the micro welding space, and I’m excited to share some of the ways these partnerships are making a real difference.

EWI: Driving Innovation and Exploring New Frontiers

While AWS and RWMA help us maintain high standards and improve existing technologies, our collaboration with EWI is where we really get to push the envelope. EWI is known for its groundbreaking work in materials joining and welding technologies, and working with them allows us to extend our welding technology into more applications.

EWI’s advanced testing facilities have also been a game-changer for us. By having access to cutting-edge tools and materials analysis capabilities, we’ve been able to expand upon our welding technology successes. Sunstone's continued innovation is driven in part by EWI’s expertise and resources.

AWS: Setting the Standard for Quality and Expertise

One of the most impactful partnerships we’ve developed over the years is with AWS, the largest welding association in the world. AWS is a powerhouse when it comes to setting industry standards, and that’s been invaluable for us at Sunstone. By leveraging our relationship with the AWS we’ve pushed our micro welding solutions to a higher level of quality than ever before. Our focus on precision welding gives our customers confidence that they’re using equipment that’s not only innovative but also reliable.

I appreciate the exchange of knowledge with other professionals in the field through the AWS. Through their conferences, technical committees, and symposiums, we’ve connected with welding experts from around the world. These connections help us stay on top of emerging trends, learn about the latest advancements in welding technologies, and continuously improve our products.

One specific area where AWS has been especially helpful is resistance welding, which plays a huge role in our micro welding applications. We’ve been able to refine our resistance welding techniques and develop machines that offer even more precision for industries like electronics, medical devices, and aerospace. AWS helps us keep the bar high, ensuring that our customers always have access to the best technology available.

RWMA: Empowering Us to Create More Tailored Solutions

Our partnership with RWMA, a subdivision of AWS, has been instrumental in helping us fine-tune our resistance welding offerings. RWMA focuses specifically on resistance welding, which is a critical aspect of micro welding in many industries, such as aerospace, electronics, EV, and more. Through their technical guidelines and best practices, we’ve been able to create welding solutions that meet the unique needs of our customers—especially those in high-precision sectors.

Take the electronics industry, for example. Many manufacturers need to weld extremely fine wires and components without damaging the surrounding materials. RWMA’s resources provide the knowledge and tools to develop welding technology that can achieve that level of precision. By reducing the risk of weld defects and improving accuracy, we’re helping these manufacturers create better products and minimize production issues.

RWMA’s focus on education is a huge asset for Sunstone. Their training programs will allow our team to build specialized skill sets, which in turn means we can offer better support and more customized solutions to our customers. When a manufacturer comes to us with a specific challenge, we’re able to leverage the RWMA library to help optimize a suitable welding process, increase efficiency, and ensure the highest level of product quality.

How These Partnerships Benefit Our Customers

What does our relationship with the best welding associations mean for the manufacturers who rely on Sunstone’s micro welding solutions?

First, it means they can trust our products to meet the highest levels of precision and reliability. Thanks to our partnerships with AWS and RWMA, we’ve been able to create welding systems that are optimized for a wide range of applications, from fine wire welding in electronics to high-strength welds in aerospace components.

Second, it means that they have access to the latest welding technologies. Our collaboration with EWI ensures that we’re constantly pushing the boundaries of what micro welding can do, through any of the welding technologies we offer.

And finally, these partnerships allow us to offer unmatched support. We don’t just provide welding technology—we work closely with manufacturers to help them optimize their welding processes, reduce downtime, and improve product quality. Whether it’s through training programs, custom solutions, or ongoing technical support, we’re committed to helping our customers get the most out of their micro welding equipment.

At the end of the day, these partnerships are about one thing: delivering the best possible solutions to meet our customers’ micro welding needs. By working with AWS, RWMA, and EWI, we’re not just advancing technology—we’re helping manufacturers around the world achieve their goals with confidence and precision.

Recent Welding Technology Impacted by Our Partners

EWI and the AWS provided much valuable input in the launch of these Sunstone products:

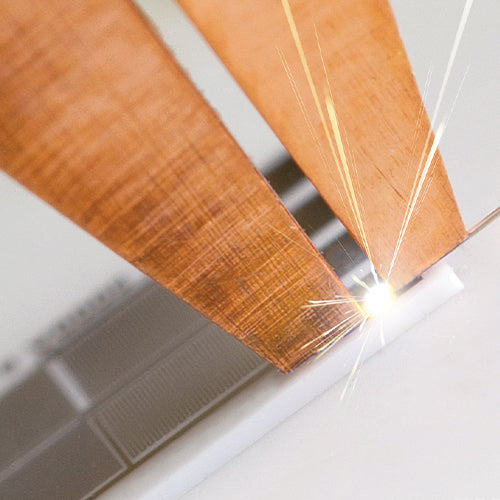

Aeon HF™. The Aeon HF is a high frequency inverter spot welder that leverages the latest technology to produce an exceptional weld for many different applications. With the Aeon HF, Sunstone has re-invented high frequency welding technology, providing manufacturers with an ultra-modern, highly precise HF welding solution.

Wave AC®. The Sunstone Wave AC is the world’s most advanced AC resistance welder capable of delivering up to 2,700 amperes and newly designed for the 21st century. Using advanced electronics, the Wave AC significantly increases energy precision resulting in improved welding results.

Pico DC™. The Sunstone Pico DC is an advanced, closed-loop feedback direct-current resistance welder specifically engineered for thermocompression or other fine welds.

Advanced CD. Sunstone’s advanced dual pulse CD welders offer many capabilities including weld monitoring, SPC tools, and a large capacitive touch-screen interface.