Oil and Drilling

Micro Welding in the Oil and Drilling Industry

Precision & Power

Sunstone Micro-Welding Systems are designed for high levels of precision for working with delicate wires, thin sheets, or precise placement of specialty parts. Sunstone Micro-Welding Systems also provide the power to accomplish a wide range of welding applications. Weld tungsten carbid to stainless steel, strain gauges, thermocouples, copper tabs for battery pack assembly, or simple tack welds. Get the accuracy, precision and power that you need!

Applications

- Oil drilling bits – tacking in place prior to hardfacing

- Mold and die repair

- EV battery pack construction

- Battery tabs

- Power cell connections that sit on ocean floors

-

Original price $7,800.00 - Original price $13,200.00Original price$7,800.00 - $13,200.00$7,800.00 - $13,200.00Current price $7,800.00| /

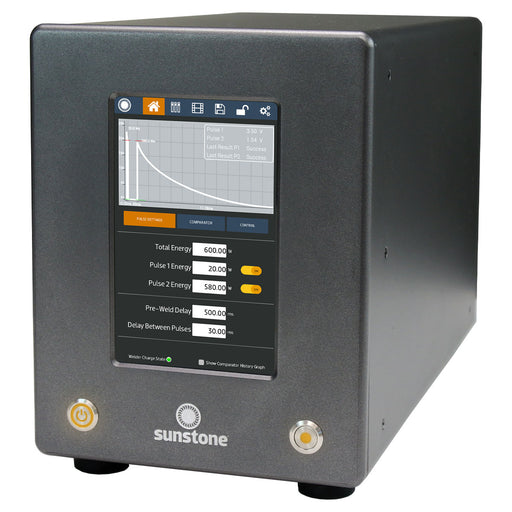

Micro Resistance - Advanced Dual Pulse CD Spot Welder

Sunstone WeldersIn stockADVANCED FINE-SPOT RESISTANCE WELDERS Feedback reporting PLC connectivity Full weld head control 200ws, 400ws, 600ws or 1200ws power Roll spot C...

View full detailsOriginal price $7,800.00 - Original price $13,200.00Original price$7,800.00 - $13,200.00$7,800.00 - $13,200.00Current price $7,800.00| / -

Original price $13,200.00 - Original price $13,200.00Original price$13,200.00$13,200.00 - $13,200.00Current price $13,200.00| /

High Power - Micro Resistance - Advanced CD Spot Welder

Sunstone WeldersIn stockADVANCED FINE-SPOT RESISTANCE WELDERS Capacitive Discharge (CD) resistance welders have many advantages over other welder types. Since CD welders u...

View full detailsOriginal price $13,200.00 - Original price $13,200.00Original price$13,200.00$13,200.00 - $13,200.00Current price $13,200.00| /