Welding is a very competitive and precise industry. If you do not have the ability, knowledge, or skills to complete a specific task, someone else will. The same applies to Micro welding. If someone can perform a better, more accurate, and more precise weld, a customer will easily choose that competitor, and you lose money.

Waveforms are one of those difficult to understand topics that are shaping the welding industry. With the knowledge and understanding of what each of these welding waveforms is and how to use them, you will be better equipped to give the customer the best possible weld, the first time.

What are The Different Waveforms?

Classic Waveform

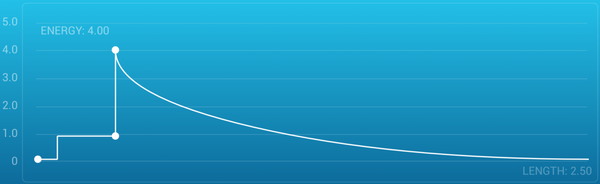

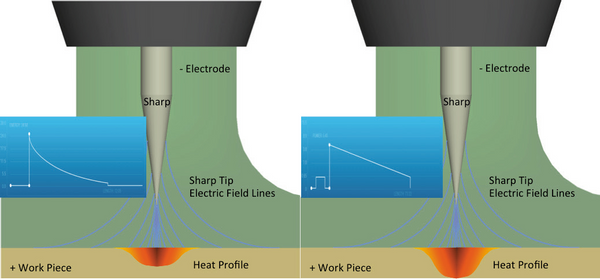

Classic Waveform is the most popular & is featured on all of the Orion welding systems. It is the most all-around versatile welding waveform that allows you to get great results, without any of the undesired side effects. The major advantage of the classic waveform is that it gives you a high peak current, that gives you an aggressive melt. This means that as you are welding the weld will join small gaps together, rather than push them apart. The classic waveform has a quick exponential downslope that provides a small heat affected zone. The one downside of the classic waveform is that it is only available in preset lengths.

Triangle Waveform

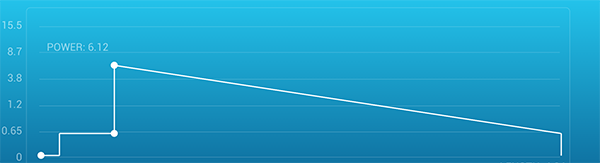

Triangle waveform Provides a smoother weld & deeper penetration compared to classic mode. Triangle Waveform allows you to get a smaller weld diameter with deeper penetration. The length adjustment will enable you to customize each weld according to the welding application. If you are looking for deep penetration, with a smaller melt spot, Triangle can help you accomplish this. Because of the gentle & Constant downslope Triangle waveform provides an even and soft cooling that allows avoiding Heat Cracking. It is essential that you are aware that Triangle Waveform Will add more heat to your workpiece. Be cautious when using triangle Waveform around temperature sensitive elements or stones. Triangle Waveform is Only available on the Orion 200i Welding System

Square Waveform

Square waveform provides even deeper penetration when compared to both Triangle Waveform, and Classic Waveform. Square waveform is especially helpful when pushing, spreading, and smoothing metal. The Current & Voltage have almost no rise time, then remain constant at the peak voltage, finally drop to zero quickly. Square waveform adds the most amount of heat in the workpiece, and caution should be used specifically when working with heat sensitive elements. Square Waveform is only available on the Orion 200i Welding System

Important Elements of Waveforms

Weld Length

When working with Square & Triangle Waveforms, length of the weld is equally important as energy. Understanding weld length, and how it affects the weld is significant. When you make a weld the metal within the weld spot becomes liquid. Understanding fluid dynamics & how liquids respond helps to understand weld length. If you were to throw a rock into a pond, it would create a splash with corresponding ripples (Like the image to the right). This pond will freeze at some point. If you allow a more extended amount of time for the ripples to smooth out slowly, you will get a smoother frozen pond. This pond is the same as welding length, the more time (ms) that you add to a weld the longer you are allowing the ripples to smooth out, and the result of your weld will be smoother.

Understanding the relationship between energy and length and how they affect the weld, will help you better customize and tailor your weld to your application. For example, if you were to have a weld with High power, with a short length. This weld combination would give you more penetration with less smoothing. On the inverse, if we had a weld with lower power, and longer length, this would allow for less penetration and more smoothing. Ideally, you will find a balance between your metal and application. A great place to start is keeping the two equal. The slider bars on the control panel are color-coded, merely keep the colors the same both in the energy slider wheel and the length slider.

Orion 200i Welding System

Square & Triangle welding waveforms add a tremendous amount of capability to your welding. They are simple to learn, and with practice become indispensable. Finding and perfecting your weld settings will save you a significant amount of time in clean up and rework. Saving time allows you to make more money, and get more done. Saving time and money is precisely what the Orion 200i was designed and built to do. To save you time and money, and make your job easier. Click below to learn more about this fantastic welding system