Defense and Military

100% Reliability from R&D to Prototype to Production

Sunstone takes pride in the assistance the company has provided to nearly every branch of the military. And government research organizations around the world have tapped Sunstone to help them find cutting edge welding solutions. So much so that Sunstone can navigate your organization’s acquisition and procurement systems. At the front line, with life and liberty on the line, you can count on a Sunstone micro welder to deliver a reliable weld time and time again.

Precise Energy Control for Expanded Flexibility

The needs of your R&D lab or particular branch of the military may be unique. Sunstone’s micro-welding specialists have experience with exotic metal combinations, aerospace engine sensors, nuclear fuel rod assemblies, solar panel cells, instrumentation, turbine component welding, honeycomb tack welding, and more!

What are you welding today? Call or text us at +1-801-658-0015.

-

Original price $7,800.00 - Original price $13,200.00Original price$7,800.00 - $13,200.00$7,800.00 - $13,200.00Current price $7,800.00| /

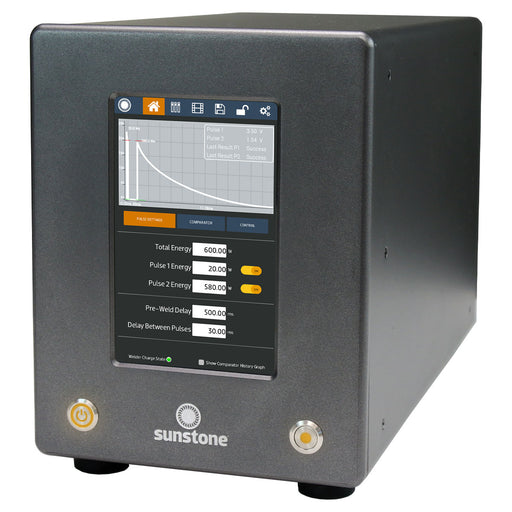

Micro Resistance - Advanced Dual Pulse CD Spot Welder

Sunstone WeldersIn stockADVANCED FINE-SPOT RESISTANCE WELDERS Feedback reporting PLC connectivity Full weld head control 200ws, 400ws, 600ws or 1200ws power Roll spot C...

View full detailsOriginal price $7,800.00 - Original price $13,200.00Original price$7,800.00 - $13,200.00$7,800.00 - $13,200.00Current price $7,800.00| / -

Original price $10,900.00 - Original price $10,900.00Original price$10,900.00$10,900.00 - $10,900.00Current price $10,900.00| /

The Pico™ - DC Closed-loop Feedback Resistance Welder

Sunstone WeldersIn stockThe Pico - DC Closed-loop Feedback Resistance Welder The Sunstone Pico DC is an advanced, closed-loop feedback direct-current resistance welder sp...

View full detailsOriginal price $10,900.00 - Original price $10,900.00Original price$10,900.00$10,900.00 - $10,900.00Current price $10,900.00| / -

Original price $15,500.00 - Original price $15,500.00Original price$15,500.00$15,500.00 - $15,500.00Current price $15,500.00| /

PA250i Micro TIG Welder

Sunstone WeldersIn stockPA250i Micro TIG Welder Maximum Power!The most powerful Sunstone pulse arc welder delivers 250 joules of energy with precision and accuracy When yo...

View full detailsOriginal price $15,500.00 - Original price $15,500.00Original price$15,500.00$15,500.00 - $15,500.00Current price $15,500.00| / -

Original price $13,200.00 - Original price $13,200.00Original price$13,200.00$13,200.00 - $13,200.00Current price $13,200.00| /

High Power - Micro Resistance - Advanced CD Spot Welder

Sunstone WeldersIn stockADVANCED FINE-SPOT RESISTANCE WELDERS Capacitive Discharge (CD) resistance welders have many advantages over other welder types. Since CD welders u...

View full detailsOriginal price $13,200.00 - Original price $13,200.00Original price$13,200.00$13,200.00 - $13,200.00Current price $13,200.00| /