What Welding Technology is Best for Aerospace Applications with Honeycomb Core?

When it comes to aerospace manufacturing, achieving lightweight, durable, and high-performance components is critical. Honeycomb core structures are a superstar in this space, delivering unparalleled strength while keeping weight to a minimum. But securing these delicate structures requires precision and the right welding technology.

In this blog, we’ll explore honeycomb’s role in aerospace, how it’s typically bonded, and why Sunstone Welders’ CD Spot Welders are the ultimate tool for the job. We’ll also cover the rigorous quality control and testing required to meet aerospace standards. Let’s dive in!

What Is Honeycomb in Relation to Aerospace Manufacturing?

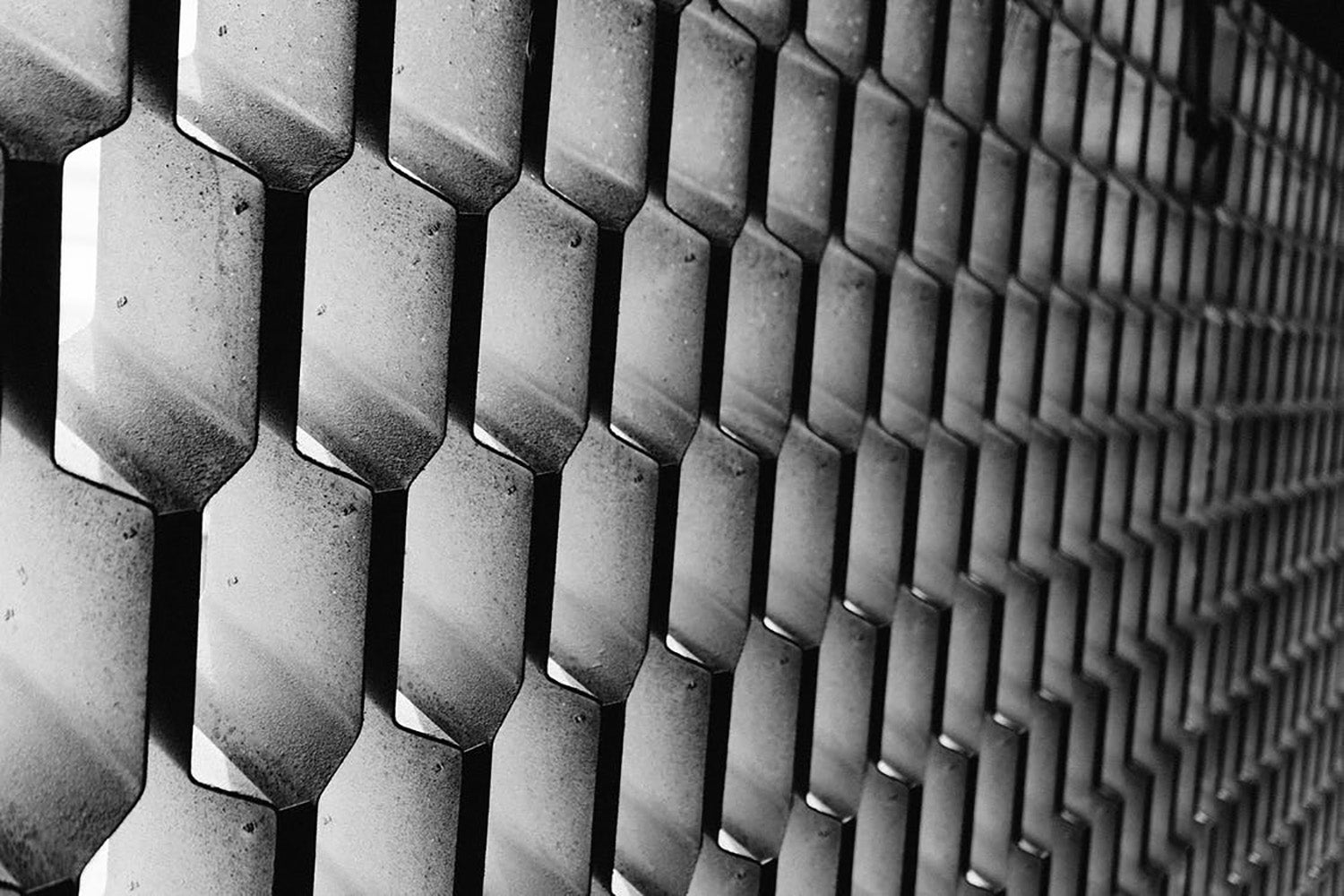

Honeycomb cores are a true marvel of engineering, mimicking the natural strength of beehives to create lightweight yet sturdy structures. These are widely used in aerospace for everything from fuselage panels to flooring and control surfaces.

Why Honeycomb?

The secret lies in its hexagonal pattern, which provides a high strength-to-weight ratio. This makes it perfect for aerospace applications where every ounce matters, yet components must endure incredible forces.

Types of Honeycomb Materials

- Aluminum: Lightweight and corrosion-resistant, a popular choice for panels.

- Nomex® (Aramid Fiber): Resistant to high temperatures and ideal for environments where fire safety is key.

- Titanium: Known for its unmatched strength and corrosion resistance in critical aerospace parts.

- Carbon Fiber: Combines rigidity and lightness for advanced applications like satellites and drones.

Each material brings unique benefits to meet specific aerospace needs.

How Is Honeycomb Typically Bonded or Welded?

To assemble honeycomb structures, manufacturers often rely on brazing. This process creates a strong bond by melting a filler material between the honeycomb core and its skins.

The Brazing Process

Here’s a quick breakdown of how brazing works:

- Choose a Brazing Material: Brazing paste and foils are used; common metal alloys include metals like nickel or silver.

- Heat in a Brazing Oven: Components are placed in an oven and heated to melt the filler, creating a durable bond.

- Secure Components: The honeycomb and skins must be held in place during heating to prevent shifting or misalignment.

While effective, brazing alone has challenges—materials must stay perfectly positioned during the process. That’s where CD spot welding comes in!

CD Tack Welding

The Perfect Solution If you’re tacking honeycomb cores before brazing, look no further than Sunstone Welders’ CD Spot Welders. These welders offer precision, reliability, and ease of use, making them a game-changer for aerospace manufacturing.

Why CD Spot Welding?

Here’s why Sunstone’s welders are perfect for this job:

Pinpoint Precision: Applies heat only where needed, protecting delicate honeycomb materials like Nomex® or aluminum.

- Speed: Tack welds are made in milliseconds, saving time during assembly.

- Versatility: Works seamlessly with different honeycomb materials, from lightweight to ultra-strong.

- Simplicity: Tack welding is quick and efficient, securing honeycomb cores in place before brazing. Want to see it in action? Check out this video!

Quality Control and Testing for Aerospace Welding

In aerospace, every weld counts. The stakes are high, and manufacturers must meet strict quality standards to ensure safety and reliability.

Non-Destructive Testing (NDT)

Welds are inspected without damaging components using techniques like:

- X-Ray: To detect hidden flaws like voids or cracks.

- Ultrasonic Testing: Uses sound waves to check weld integrity.

- Thermography: Infrared imaging identifies heat inconsistencies that could signal weak spots.

Shear and Tensile Testing

To handle the extreme stresses of flight, welds must pass rigorous tests:

- Shear Testing: Ensures resistance to lateral forces.

- Tensile Testing: Verifies welds won’t fail under tension or pulling forces.

Meeting Industry Standards

Every weld must meet aerospace certification standards, including:

- FAA Guidelines: Ensures airworthiness and safety compliance.

- AS9100 Certification: Aerospace-specific quality management.

- AWS D17.1/D17.2: Welding specifications for aerospace hardware.

Real-Time Monitoring

Sunstone’s CD Spot Welders take quality to the next level with real-time monitoring of weld parameters like current and voltage. This ensures consistency and traceability in production, reducing errors and saving valuable time.

Environmental and Fatigue Testing

To ensure long-term reliability, honeycomb welds are tested for:

- Vibration Resistance: Simulates the constant vibration of flight.

- Temperature Cycling: Ensures welds hold up under freezing and high-heat conditions.

- Corrosion Resistance: Verifies that materials withstand harsh environments over time.

With Sunstone’s advanced welding technology, you can confidently meet these challenges and deliver reliable aerospace components.

Why Choose Sunstone Welders?

Precision, speed, and reliability are just the beginning. Sunstone Welders’ CD Spot Welders are designed to meet the exacting demands of aerospace manufacturing while making your job easier.

If you’re ready to take your honeycomb welding process to the next level, contact Sunstone Welders today and discover how our solutions can help you achieve perfection in every weld.

For honeycomb welding, explore the advanced Sunstone CD welder!